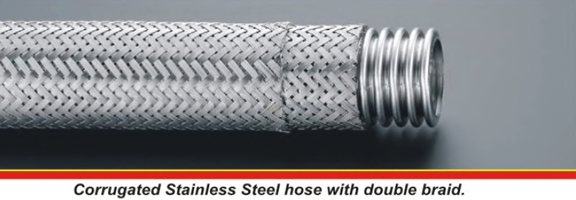

To give corrugated hose the ability to withstand pressure, stainless steel wire is braided over the hose. Hose may be single braided ( one layer of braid ) or double braided ( two layers of braid ) to achieve even greater working pressures. Braided braid is used on large diameter hose. Designing the proper braid for each type of corrugated hose requires sophisticated engineering to maintain the proper balance between the braid strength and the hose flexibity. Hosexperts braid packages offer several advantages.

working pressure de-rating factor |

||

|---|---|---|

Temprature In Degrees F |

321/316/316L |

304 |

| 70 | 1.00 | 1.00 |

| 150 | 0.97 | 0.96 |

| 200 | 0.94 | 0.92 |

| 250 | 0.92 | 0.91 |

| 300 | 0.88 | 0.86 |

| 350 | 0.86 | 0.85 |

| 400 | 0.83 | 0.82 |

| 450 | 0.81 | 0.80 |

| 500 | 0.78 | 0.77 |

| 600 | 0.74 | 0.73 |

| 700 | 0.70 | 0.69 |

| 800 | 0.66 | 0.64 |

| 900 | 0.62 | 0.58 |

| 1000 | 0.60 | - |

| 1100 | 0.58 | - |

| 1200 | 0.55 | - |

| 1300 | 0.50 | - |

| 1400 | 0.44 | - |

| 1500 | 0.40 | - |

Temperature Correction Factors For Elevated Temperature Applications. |

|---|

|

As the service temperature increases, the maximum pressure a hose assembly can withstand decreases. The material from which the hose is made and the method of fitting attachment (mechanical, soldered, welded, silver brazed) determines the maximum pressure at which an assembly can be used. To calculate the working pressure de-rated for elevated temperatures, multiply the hose working pressure by the appropriate de-rating factor shown in the table. |

For further details, kindly download the catalogue.

© Copyright 2017, all rights reserved with HoseXperts, New Delhi (India)